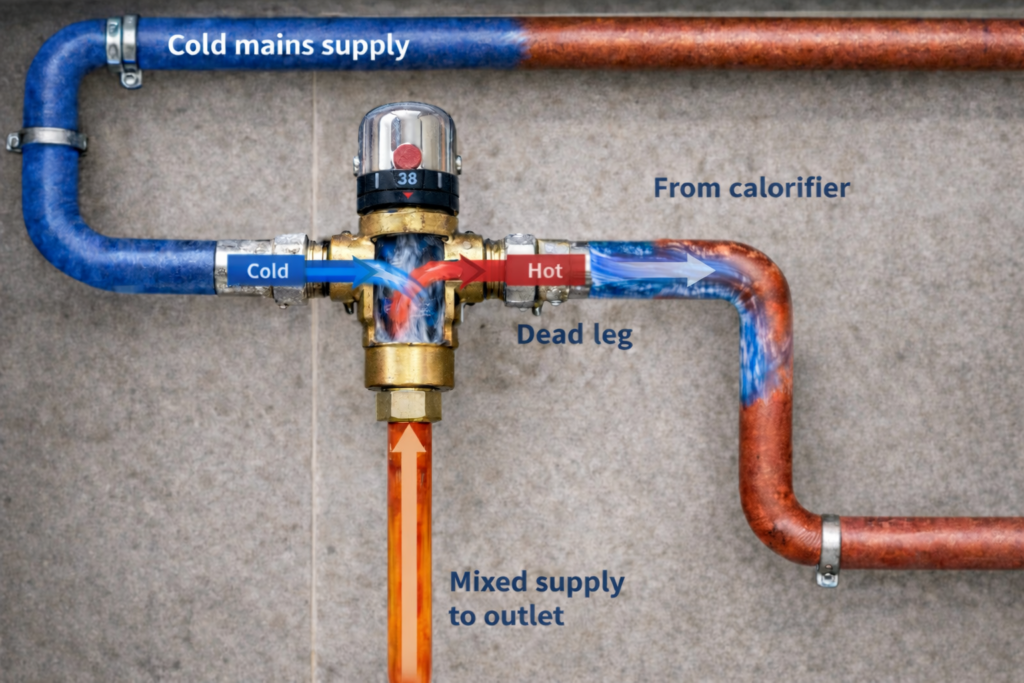

Passing TMVs create the exact conditions Legionella bacteria thrive in.

The combined effects include:

- Temperature mixing that keeps water within the 20–45°C growth range

- Reduced flow and stagnation caused by circulation interference

- Dead legs that allow water to sit undisturbed

- Loss of thermal control in both hot and cold systems

Once temperature control is lost, biofilm rapidly develops on internal pipe surfaces. Biofilm acts as:

- A protective habitat for Legionella bacteria

- A nutrient source for ongoing bacterial growth

- A barrier that reduces the effectiveness of temperature control and disinfection

As biofilm thickens, it further restricts flow, worsening stagnation and creating a self-reinforcing cycle that accelerates colonisation.

In many investigations of persistent Legionella positives, passing TMVs are identified as a key contributing factor – particularly where multiple outlets show contamination despite compliant plant temperatures.

Why TMVs Start Passing

Passing TMVs are rarely sudden failures. In most cases, they develop gradually due to poor maintenance or incorrect installation.

Common causes include:

- Lack of routine TMV servicing

- Missing, blocked, or damaged inlet strainers

- Debris accumulation on check valves

- Check valves sticking in the open position

Without effective strainers, scale, corrosion products, and debris enter the valve body and lodge on the check valves, preventing proper sealing and allowing cross-flow between hot and cold supplies.

Why This Is a Serious Water Safety Risk

Passing TMVs don’t just affect user comfort or scald protection. They compromise system control, making it extremely difficult to manage Legionella risk.

Consequences include:

- Inability to maintain compliant hot and cold temperatures

- Creation of hidden dead legs and low-flow zones

- Accelerated biofilm growth

- Increased likelihood of Legionella colonisation

- Repeated positive sample results with no obvious cause

Because the symptoms often appear elsewhere in the system, TMVs are frequently overlooked during investigations.

Preventing TMV Passing and Reducing Risk

Passing TMVs are largely preventable with proper management.

Best practice includes:

- Routine TMV servicing in line with manufacturer guidance

- Inspection and cleaning of inlet strainers

- Functional testing of check valves

- Replacement of worn or sticking components

- Verification of temperatures and flow after maintenance

TMV maintenance should be viewed as a core Legionella control measure, not just a scald prevention task.

Final Thoughts

TMVs may be point-of-use devices, but their failure can have system-wide consequences. Passing cold into hot or hot into cold undermines temperature control, disrupts circulation, encourages biofilm formation, and significantly increases the risk of Legionella colonisation.

Where unexplained temperature failures or persistent microbiological issues exist, TMVs must always be considered as part of the investigation – particularly where servicing regimes are inadequate or incomplete.

Proper TMV maintenance protects not just users, but the integrity and safety of the entire water system.

Leave a Reply

You must be logged in to post a comment.